AlpHa Measurement Solutions |

pH in Power Generation

pH in Power Generation

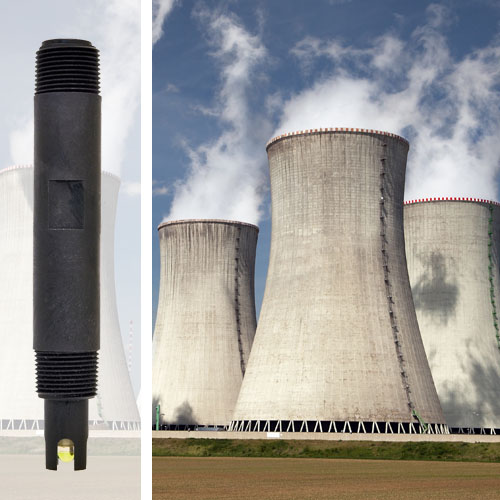

pH monitoring and control is a required parameter throughout the power generation process. For example, in coal-fired power plants, flue gas desulfurization scrubbers remove sulfur dioxide before it is released out the stack. The pH of the slurry in the absorber must be kept at a specific pH range to properly perform the sulfur dioxide removal from the flue gas and reduce maintenance costs, chemical use, and decrease equipment wear.

Boiler water with pH outside of operating range can lead to turbine failure, condenser failure, and corrosion issues throughout the piping system. The high temperatures of boiler water present unique challenges to the sensor design.

pH is a critical parameter to monitor and control in cooling tower water to avoid build up of silica and calcium carbonate scale. Inhibitors are added to cooling towers to reduce scale, however, they are ineffective if not within the specified pH range.

pH sensors are often located in remote areas for power generation applications. Sensor maintenance can be minimized with the appropriate sensor design, in particular, the housing material, reference junction, and reference electrolyte. This is critical as sensors are often located in remote areas.

- pH Range: 0 to 14 pH

- Response Time: 10s

- Low Ionic Strength Response Time: < 30s

- Drift: ±0.05 pH (in 24 hours)

- Accuracy: ±0.02 pH

- Temperature Range: -5 to 135°C

- HF Resistant

- Tuff-Tip Option

- Customer Mechanical Assemblies Available

- Low Ionic Strength Option

- Warranty: 12 Months

- Form Factor

- 12 mm

- Process Body

- Cartridge

- Custom Options Available

- Housing Material Options

- Ryton® (PPS)

- ABS

- Epoxy

- Polycarbonate

- Kynar ® (PVDF)

- Polyethylene

- PEEK

- PVC / CPVC

- Teflon ™ (PTFE)

- Ultem® (PEI)

- Metal

- Stainless Steel

- Other Metals Available

- Glass

- Metal

- Thermistor Options

- PT100 (type A & B)

- PT1000

- 10 kohm

- 30 kohm

- 100 kohm

- Any commercially available thermistors and custom options

- Common temperature accuracy is ±0.3 °C and can vary based on thermistor option chosen

- Reference System

- Ag / AgCl

- Differential

- Custom Options Available

- Reference Junction Options

- Double Junction

- Single Junction

- Custom Options Available

- Reference Junction Material / Design

- Ceramic Pin / Annular / Disc

- Fiber / Pellon

- Porous Plastic (PTFE / HDPE / PP)

- Sleeve Junction / Free Flow (liquid / liquid or ground glass joint)

- Open Aperture

- Solid State

- Custom Options Available

- Solution Ground

- Integrated in Thermowell

- Integrated in Body Housing

- Stand-alone

- Custom Options Available

- Reference Electrolyte

- Sealed

- Soft Gel

- Solid Gel

- Refillable

- Liquid

- Soft Gel

- Custom Options Available

- Sealed

- Glass Sensor Shape

- Bulb

- Dome

- Flat

- Semi Micro

- Integrated Insertions

- 3/4" NPT

- 1/2" NPT

- 1" NPT

- PG 13.5

- Custom Options Available

- Analog

- Millivolts

- 4 – 20 mA

- 0 – 5 V

- 0 – 10 V

- Custom Options Available

- Custom options available with preamp capabilities

- Digital

- RS-485 MODBUS RTU

- Custom Options Available

- Connectors

- Integrated Connectors (detachable or cableless)

- S7

- S8

- Integrated BNC

- Variopin

- Custom Options Available

- Connectors with Cables (including temperature)

- BNC

- DIN

- MOLEX

- Mil-spec

- 2.5 mm/3.5 mm phono

- RCA

- Spade Lugs

- Tinned Leads

- LEMO

- Circular Connectors

- Any commercially available connectors and custom options available

- Integrated Connectors (detachable or cableless)