Temperature measurement is a fundamental requirement in most industrial processes. From monitoring water quality to ensuring safe food processing, accurate temperature readings form the backbone of process control, product consistency, and safety assurance. Because temperature directly affects chemical reactions, biological activity, and physical properties, selecting the right sensor is essential. Among the most common temperature sensors are NTC thermistors (Negative Temperature Coefficient devices) and RTDs (Resistance Temperature Detectors). Both work on resistive measurement principles, but behave differently as temperature changes. This article reviews the differences between NTC vs RTD sensors, including their working principles, applications, and choosing the best option. Additionally, we will review AlpHa’s role in developing advanced temperature sensors that meet the diverse requirements of various industries.

What Is an NTC Sensor?

NTC sensors, also known as thermistors, are resistive devices whose resistance decreases as the temperature increases. Consisting of ceramic or polymer-based materials, NTC sensors are extremely sensitive in a limited temperature range.

Their small size, affordability, and rapid response time make them a popular choice in consumer electronics, automotive systems, and medical devices. For example, NTC sensors can quickly detect temperature changes in battery packs, HVAC systems, or even digital thermometers. While they excel in responsiveness, they are less stable at extreme temperatures and may drift over time. Nonetheless, in applications where speed and cost efficiency matter more than absolute precision, NTC sensors remain indispensable.

What Is an RTD Sensor?

RTD stands for Resistance Temperature Detector, and as the name suggests, it relies on the principle that the resistance of a conductor increases with rising temperature. Platinum is the preferred material for RTDs, with Pt100 and Pt1000 being industry-standard configurations.

RTDs are celebrated for their linearity, stability, and wide temperature range, typically from -200°C up to +850°C. This makes them the sensor of choice in industrial process control, laboratory environments, and power generation systems.

Compared to NTC thermistors, RTDs tend to be larger and more fragile, but they deliver unparalleled accuracy and long-term repeatability. Their standardization also makes them compatible across industries, which simplifies system integration.

Working Principle of NTC vs RTD

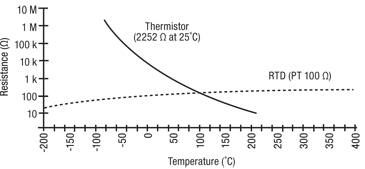

The fundamental difference between NTC and RTD sensors lies in their resistance-temperature relationship.

- NTC thermistors show an exponential decrease in resistance as temperature rises. This makes them highly sensitive in narrow ranges but more difficult to interpret across wider spans.

- RTDs, on the other hand, exhibit a linear increase in resistance with rising temperature. This predictable behavior enables precise measurement across broad temperature ranges.

Engineers often visualize this difference with resistance-vs-temperature graphs, as shown in the figure below. An NTC (Thermistor) curve appears steep at lower temperatures and flattens as temperature increases. Whereas an RTD curve is a near-straight line, enabling consistent calibration.

Advantages of NTC Sensors

NTC thermistors have several strengths:

- Cost-Effective: They are generally cheaper to manufacture and purchase than RTDs.

- Compact Size: Their small form factor makes them easy to integrate into tight spaces.

- High Sensitivity: Particularly effective for detecting small temperature changes within limited ranges.

- Fast Response Time: Ideal for applications where rapid temperature shifts occur.

Disadvantages of NTC Sensors

Despite their advantages, NTC thermistors also present limitations:

- Narrow Temperature Range: Typically effective only within a temperature range of -50°C to +150°C.

- Non-Linear Response: Requires compensation or complex electronics to interpret values.

- Lower Stability: Can drift with time, especially under prolonged thermal stress.

- Application Specificity: Performance varies significantly with design and environment.

Advantages of RTD Sensors

RTDs bring unmatched precision and consistency:

- High Accuracy: Standard platinum RTDs provide accuracy up to ±0.1°C.

- Wide Temperature Range: Suitable for extreme conditions, from cryogenic applications to industrial furnaces.

- Excellent Stability: Minimal drift makes them ideal for long-term measurements.

- Linearity: Easier to calibrate and integrate into control systems.

- Standardized Designs: Pt100 and Pt1000 configurations ensure cross-compatibility.

Disadvantages of RTD Sensors

Their high performance comes with trade-offs:

- Higher Cost: Platinum RTDs are more expensive than NTC thermistors.

- Slower Response Time: A Larger mass leads to slower equilibration compared to thermistors.

- Fragility: Thin platinum wires and protective elements make RTDs more delicate.

- Installation Complexity: More care is necessary to prevent mechanical damage during use.

Summary of Differences Between NTC Sensor vs RTD Sensor

| Feature | NTC Sensor (Thermistor) | RTD Sensor (Platinum) |

| Response Time | Fast | Moderate |

| Accuracy | Moderate | High |

| Temperature Range | Narrow (-50°C to 150°C) | Wide (-200°C to 850°C) |

| Stability | Lower | Higher |

| Cost | Low | Higher |

| Durability | Robust and compact | Fragile in some designs |

| Applications | Consumer, medical, electronics | Industrial, scientific, energy |

How to Choose Between NTC vs RTD

The choice between NTC and RTD depends heavily on your application’s requirements:

- Accuracy: For laboratory precision or regulatory compliance, RTDs are the clear winner.

- Temperature Range: If the system operates across a wide span, choose an RTD.

- Response Time: For rapid detection of changes, such as in electronics or medical sensors, NTC is most effective.

- Cost: For budget-sensitive projects, NTC provides a cost-effective solution.

- Long-Term Stability: For continuous, critical monitoring, RTDs outperform thermistors.

In simple terms:

- NTC thermistors are suitable for fast-response, cost-conscious applications within limited temperature ranges.

- RTDs excel in demanding environments that require accuracy, stability, and reliability.

Temperature Measurement in Water Quality Monitoring

Temperature plays a vital role in water quality monitoring when combined with parameters such as pH, conductivity, and dissolved oxygen. Variations in temperature affect:

- Biological growth and activity in natural ecosystems.

- Mineral solubility in ground and surface waters.

- Contaminant concentration in industrial effluents.

- The performance of chemical and physical processes in treatment facilities.

In these contexts, both NTC and RTD sensors are deployed. For example, RTDs may be integrated into multiparameter sondes for environmental monitoring, while NTC thermistors may serve as embedded sensors within electrodes. The compatibility of the thermistor or RTD with the instrumentation is critical to ensure accurate compensation and reliable results.

Challenges in Temperature Sensor Design

When integrating temperature sensors into systems, engineers must evaluate several factors:

- Thermistor Compatibility with Instrumentation.

- Accuracy and Range Requirements.

- Response Time Needs.

- Form Factor for Mechanical Insertion.

- Environmental Durability.

These considerations influence whether an NTC or RTD is better suited for the task.

AlpHa’s Expertise in Temperature Sensors

At AlpHa Measurement Solutions, we understand that no two applications are the same. That’s why we offer both NTC thermistors and RTDs, carefully integrated into robust housings with tailored form factors, housing materials, and connectors.

Our solutions go beyond standalone devices. In electrodes and multiparameter systems, AlpHa incorporates temperature compensation electronics to correct readings and maintain accuracy under variable conditions. For water quality applications, this ensures that fluctuating temperatures do not distort parameters like pH, dissolved oxygen, and conductivity.

Key highlights of AlpHa’s temperature sensor capabilities include:

- Wide operating ranges with ±0.02°C accuracy.

- Custom mechanical assemblies for specific insertion requirements.

- Housing options such as CPVC, stainless steel, PTFE, and more.

- Integration into multiparameter sondes for comprehensive monitoring.

- Options for both thermistor-based and RTD-based configurations.

By combining deep expertise with customizable solutions, AlpHa empowers industries to achieve precise, stable, and reliable temperature measurements. Contact us today to discover how our temperature sensor technologies can elevate your water quality monitoring and industrial measurement applications.