Sensors are the backbone of modern measurement and control systems. From industrial process automation to water quality monitoring, they deliver the necessary data to make timely and informed decisions. However, not all sensors communicate in the same way. Some rely on analog signals, which continuously vary in proportion to the measured parameter, while others use digital signals, which encode measurements into discrete formats. The choice between analog vs digital sensors can influence accuracy, integration, cost, and long-term reliability. Selecting the right technology is not simply a matter of preference; it is about aligning sensor capabilities with the specific needs of the application. This article examines analog and digital sensors, highlighting their advantages and limitations, comparing their performance, and offering guidance on selecting the most suitable option for your system.

What Are Analog Sensors?

Analog sensors are the traditional workhorses of measurement technology. They generate a continuous output signal, typically a voltage (e.g., 0–5 V) or current (e.g., 4–20 mA), that is directly proportional to the measured parameter.

For example, a thermocouple produces a small voltage that varies with temperature, while a strain gauge alters resistance when mechanical stress is applied. In water quality monitoring, analog pH electrodes produce millivolt signals that represent hydrogen ion activity.

Advantages of Analog Sensors

- Simplicity: Analog sensors require minimal electronics and can directly connect to basic displays or controllers.

- Fast Response: Their continuous nature enables near-instantaneous signal changes.

- Low Cost: Many analog sensors are inexpensive, making them ideal for cost-sensitive applications.

- Universal Compatibility: Most controllers and instrumentation can interpret analog signals.

Limitations of Analog Sensors

- Noise Susceptibility: Analog signals degrade over long distances or in electrically noisy environments.

- Signal Loss: Voltage drops and resistance in wiring can distort results.

- Calibration Drift: Over time, analog sensors may require more frequent recalibration.

- Limited Data Integration: Without additional electronics, analog sensors cannot provide advanced features like data logging or remote diagnostics.

What Are Digital Sensors?

Digital sensors are a more modern approach to measurement. Instead of producing a continuous signal, they encode measurements into digital data, such as binary code or structured communication protocols like RS-485, MODBUS, I²C, or SDI-12. Unlike analog sensors, many digital sensors contain built-in electronics that process raw data, apply compensation algorithms, and output clean, ready-to-use measurements. For example, a digital turbidity sensor not only measures light scattering but also corrects for temperature and drift, then outputs a digital value.

Advantages of Digital Sensors

- High Accuracy: Digital signals are less affected by noise and interference.

- Long-Distance Transmission: Data can travel farther without degradation, ideal for remote monitoring.

- Advanced Features: Many digital sensors feature diagnostics, data storage, and self-calibration capabilities.

- Easy Integration: Digital protocols connect seamlessly with modern control systems, SCADA, and cloud platforms.

- Multi-Parameter Capability: Some digital platforms integrate multiple parameters into a single unit.

Limitations of Digital Sensors

- Higher Initial Cost: Built-in electronics and communication features increase the upfront cost.

- Complexity: They require controllers, software, or systems that support their communication protocols.

- Processing Delay: Although small, digital conversion can introduce slight response delays compared to pure analog.

- Compatibility: Not all control systems natively support every digital format.

Selection Criteria: Choosing Between Analog vs Digital Sensors

When deciding between analog and digital sensors, several factors should guide your decision.

Application Environment

For controlled lab conditions, analog sensors may suffice. However, in industrial environments with electrical noise or long cable runs, digital sensors ensure reliable performance.

Signal Transmission Distance

Analog signals degrade rapidly over distance, especially those based on voltage. If your system requires monitoring across long distances, digital sensors with RS-485 or wireless outputs are more effective.

Integration Needs

Analog sensors can connect directly to simple meters, but digital sensors integrate seamlessly with PLCs, SCADA systems, and IoT platforms. If your system requires real-time logging, cloud integration, or automation, digital is the better choice.

Accuracy and Stability Requirements of Analog vs Digital Sensors

For regulatory compliance, such as in drinking water monitoring or pharmaceutical manufacturing, digital sensors provide the reliability and stability needed. Analog sensors, while accurate, can be prone to drift and environmental interference.

Cost Considerations

Analog sensors are more affordable upfront but may require frequent calibration and maintenance. Digital sensors initially cost more but reduce labor costs and downtime through automation and self-diagnosis.

Maintenance and Longevity of Analog vs Digital Sensors

If reducing manual sampling and calibration is a priority, digital sensors with self-cleaning or automated calibration features are advantageous. Analog sensors, though simpler, demand more hands-on maintenance.

Application Examples

Water Quality Monitoring

Analog pH probes remain common in basic monitoring setups, but digital multiparameter sondes dominate advanced systems. For example, AlpHa’s sonde (digital multiparameter sensor) integrates pH, conductivity, dissolved oxygen, turbidity, etc, into a single device with remote data access. We also offer single digital sensors for each of these parameters and more, with customizations if necessary.

Industrial Automation

Analog pressure sensors are still used for local monitoring, but digital, MODBUS-enabled sensors are preferred in distributed control systems, where precise data integrity is crucial.

Environmental Monitoring

For field deployments, digital sensors provide stable data transmission over long distances and support logging in remote stations, making them indispensable for climate and water research.

Food and Beverage Processing

Analog sensors work for routine measurements, but digital sensors ensure compliance with stringent quality standards, reduce contamination risks, and integrate seamlessly into automated production systems.

Hybrid Approaches: The Best of Both Worlds

It is worth noting that analog and digital technologies often coexist. Many modern monitoring systems accept both analog and digital inputs. For instance, an analog sensor can connect to an analog-to-digital converter (ADC), allowing for integration into a digital system.

This hybrid approach offers flexibility: users benefit from the simplicity and low cost of analog sensors while leveraging the accuracy and automation of digital data processing.

Recent Trends in Sensor Technology

The sensor industry continues to evolve, blending analog and digital strengths:

- Smart Sensors: Digital platforms that integrate multiple parameters and self-diagnostics.

- Wireless Transmission: Bluetooth and IoT connectivity extend digital sensor usability. For example, AlpHa’s XCITE Measure app provides a platform for the seamless integration of Bluetooth-enabled fluorometers and your mobile device. This app offers several features, including live parameter display, data logging and storage, photo documentation of test events, and export options via email or app integration.

- Low-Power Designs: Ideal for field and remote deployments.

- Ruggedization: Sensors are now engineered for extreme environments, ensuring durability in industries like mining, wastewater treatment, and marine monitoring.

These trends suggest that while analog sensors will remain relevant for simple applications, digital sensors are rapidly becoming the standard in advanced monitoring.

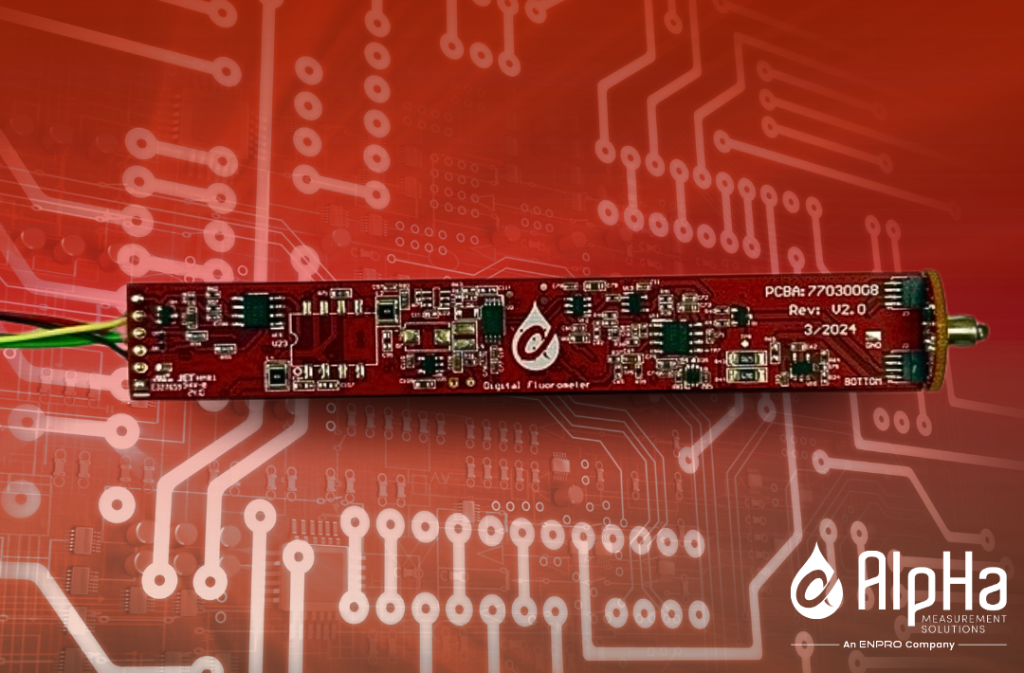

AlpHa’s Role in Sensor Innovation

At AlpHa Measurement Solutions, we recognize that no single sensor type is suitable for every application. That is why we design and manufacture sensors that support both analog and digital outputs, giving users unmatched flexibility.

AlpHa’s Sensor Capabilities Include:

- Analog Outputs: Millivolt, 0–5V, and 4–20mA signals for universal compatibility.

- Digital Outputs: RS-485 MODBUS RTU for seamless integration with industrial systems.

- Single/Multi-Parameter Platforms: AlpHa’s sondes combine pH, turbidity, conductivity, dissolved oxygen, and temperature into one customizable system. We also offer sensors that measure a single parameter, thus offering the flexibility in measurements that you need.

- Custom Designs: Tailored housings, materials, and connectors to suit specific industrial or environmental needs.

- Rugged Construction: Built for reliability in demanding applications, from municipal water treatment to marine monitoring.

With AlpHa, users do not have to choose between analog and digital; they can have both integrated into a single platform that evolves with their needs. Contact us today to learn how our innovative sensor platforms can help you achieve accurate, reliable, and future-ready measurement solutions.